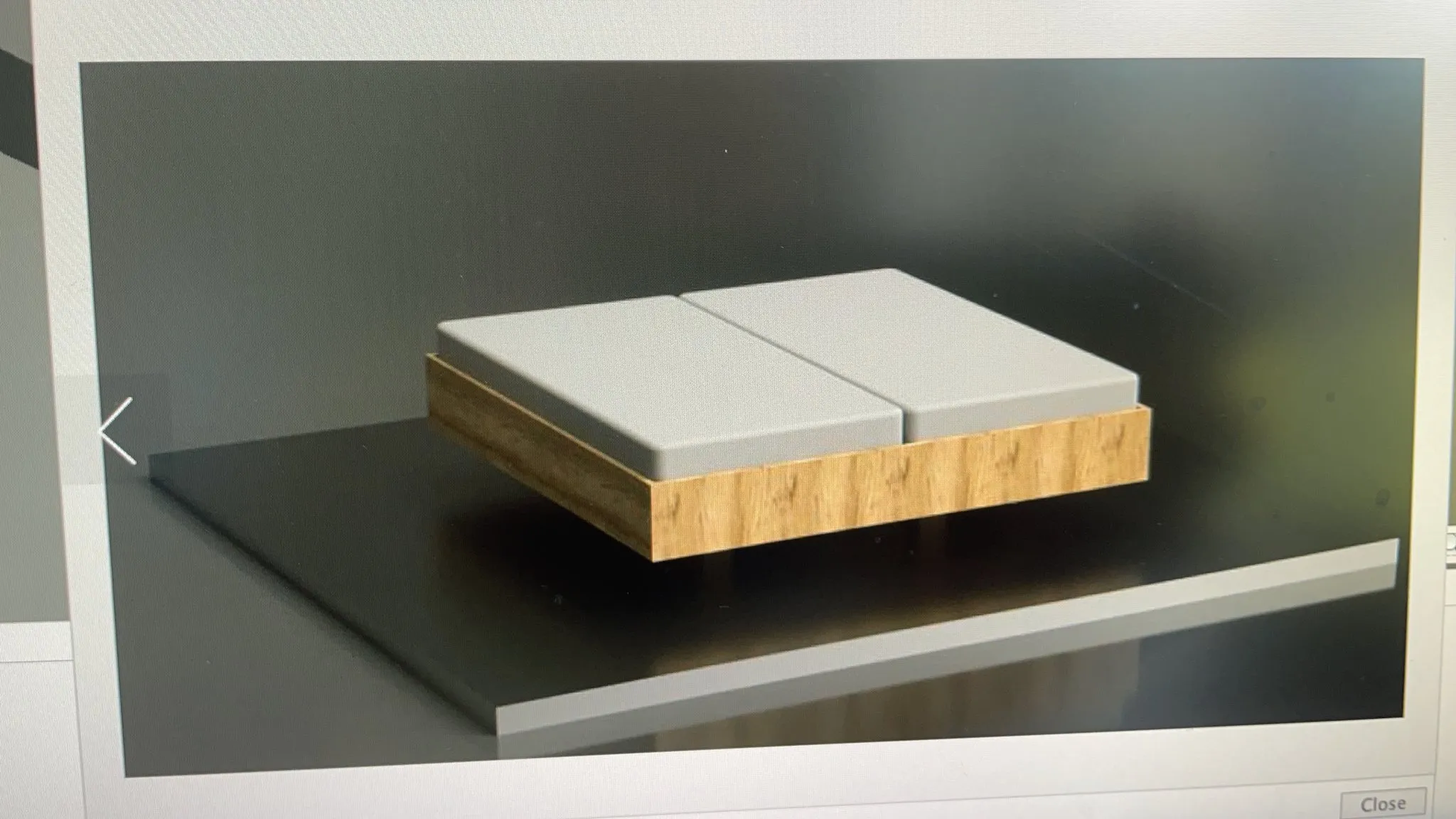

A custom-designed, floating oak bed frame built to be robust, disassemblable, and visually striking. This project involved extensive planning, new tooling, and a mix of softwood structure with a solid oak finish.

The core idea was to create a bed that appeared to float, achieved by setting the base inwards and adding under-bed lighting to enhance the hovering effect. Despite this airy look, the bed needed to be incredibly strong and wide (2m x 2m).

A key requirement was the ability to disassemble the frame for future moves. We also designed it with adjustable support to ensure comfort and longevity. The design process involved multiple iterations, with some concepts being rejected in favor of more practical solutions.

Total Budget

€4,000 total project budget covering frame, mattresses, slat system, and tools

Mattresses

€1,000 each for two separate mattresses, allowing for individual positioning and comfort preferences

Slat System

€200 each for two Lattenrost adjustable slat systems, providing individual support customization

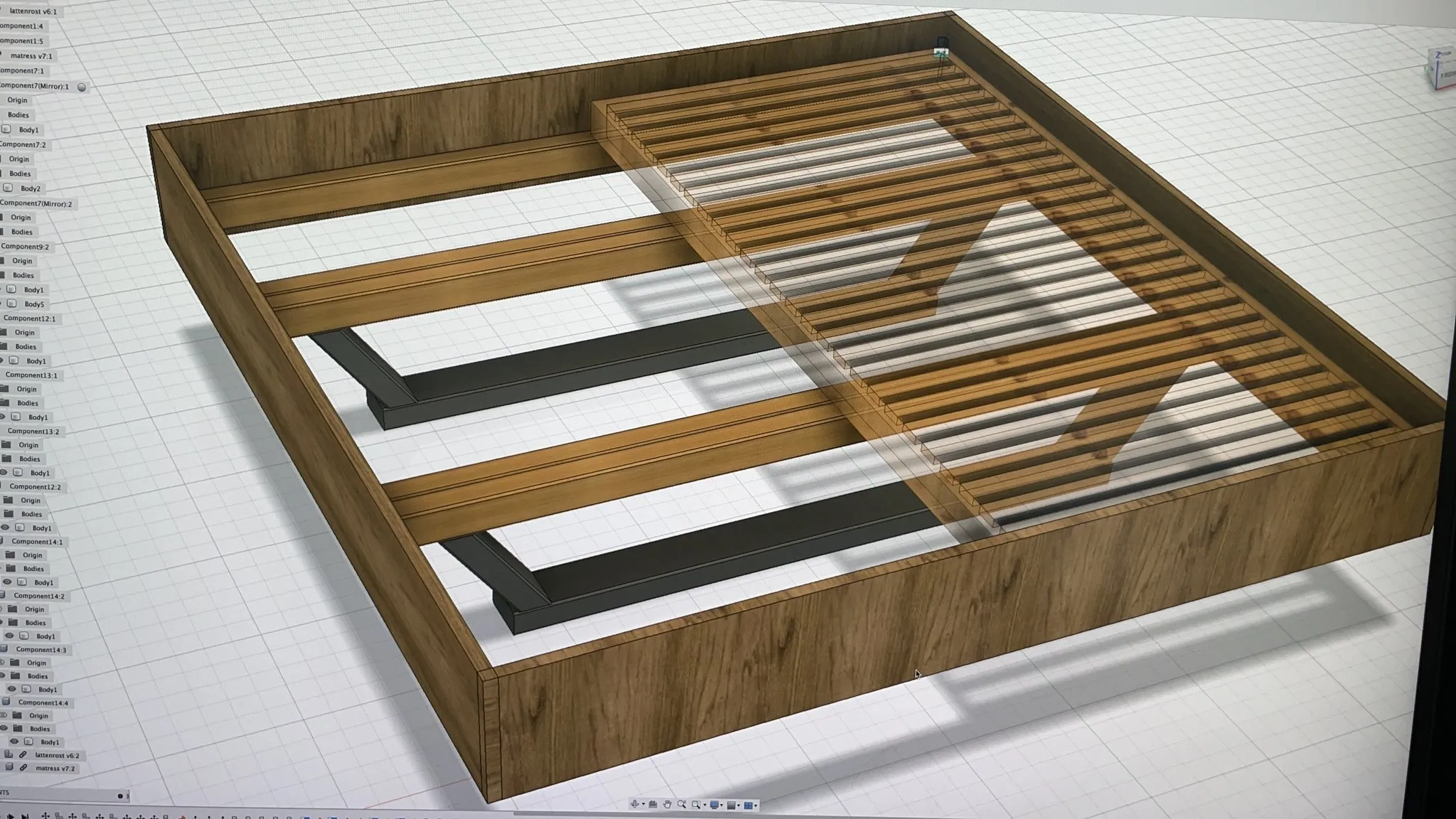

The initial planning phase involved 3D modeling to visualize the structure and explore different design approaches. Some concepts were refined or rejected based on practical constraints and aesthetic goals.

Not all design concepts made it to the final build. Some approaches were rejected due to structural concerns, manufacturing complexity, or because they didn't achieve the desired floating aesthetic. These rejected concepts helped refine the final design by highlighting what didn't work.

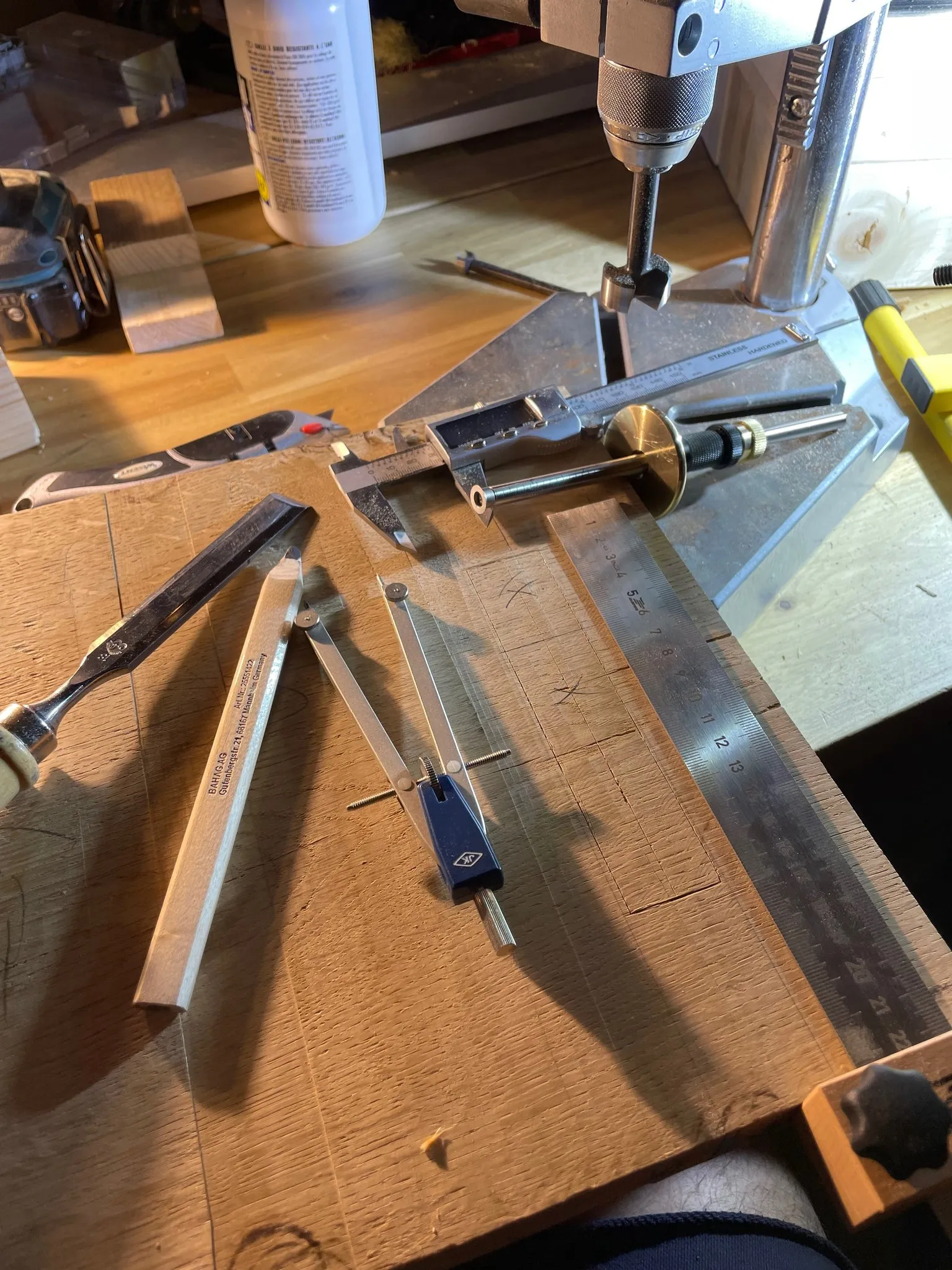

Before cutting any wood, we went through a rigorous planning phase. This involved 3D modelling to visualize the structure and running tests to figure out the best joinery methods for the oak.

Testing was crucial to avoid costly mistakes. We experimented with different joint techniques, tested wood thicknesses, and validated our approach with small-scale prototypes. Some test pieces were rejected when they didn't meet our strength or aesthetic requirements.

Test Process

Small-scale prototypes used to validate joinery methods before full construction

Material Validation

Testing revealed that some prepped oak was too thin for structural use

Some test approaches didn't meet our requirements and were rejected. These failed tests were valuable learning experiences that helped us refine our techniques and avoid mistakes in the final construction.

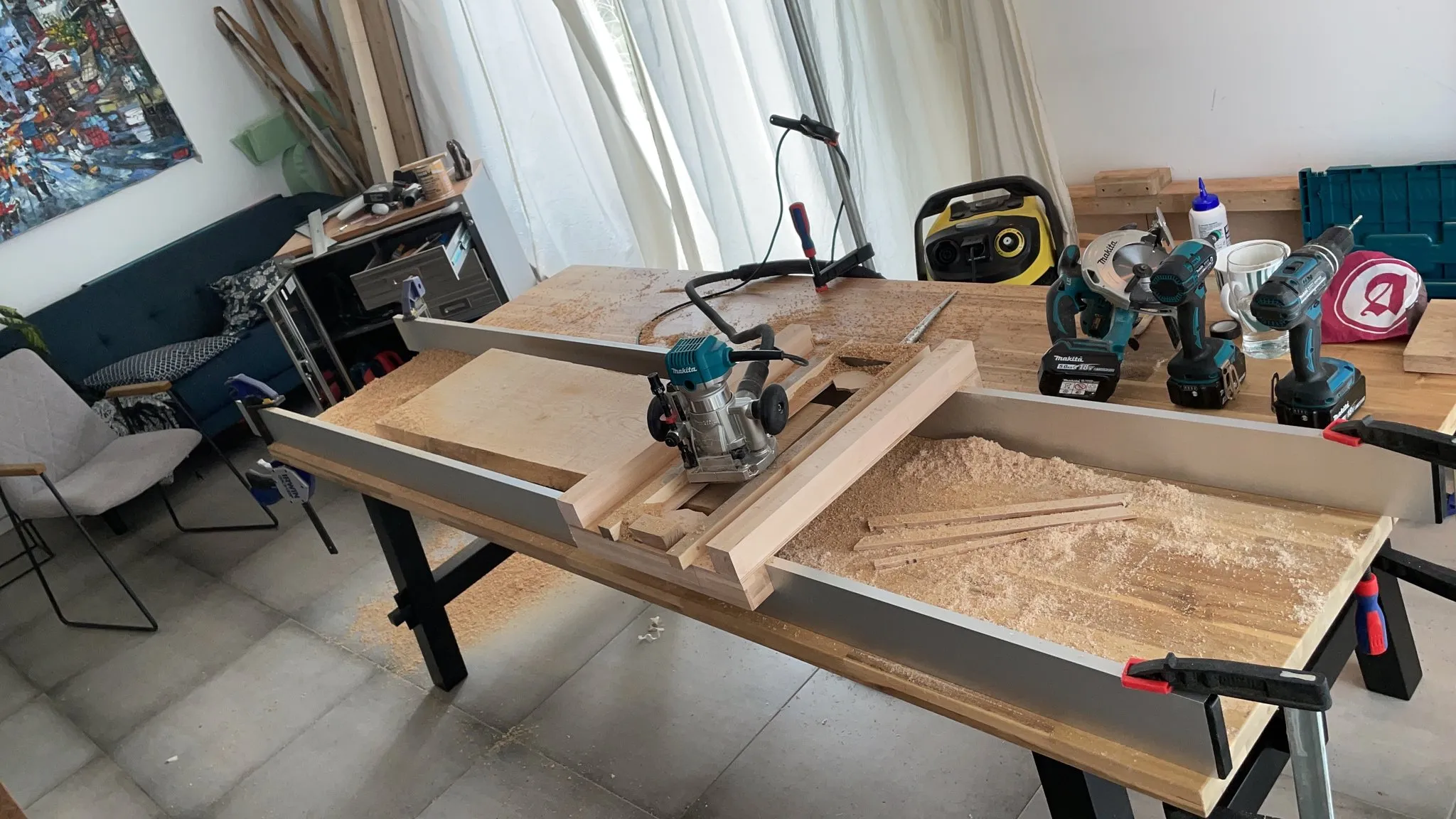

The project utilized softwood for the structural core and very rough oak logs for the visible exterior. Preparing the oak was a massive task that required new tools and custom jigs.

New Tools

Approximately €700 invested in new table saw and router equipment essential for the project

Assembly

Designed for disassembly with carefully planned connection points and hardware

Durability

The bed has successfully moved house with us 4 times, proving the disassembly design works perfectly

The preparation process began with moisture checking the rough wood to ensure it was properly conditioned. Without a track saw, creating one straight edge required careful setup and technique. Once we had a reference edge, we could rip the rough planks to size using the new table saw.

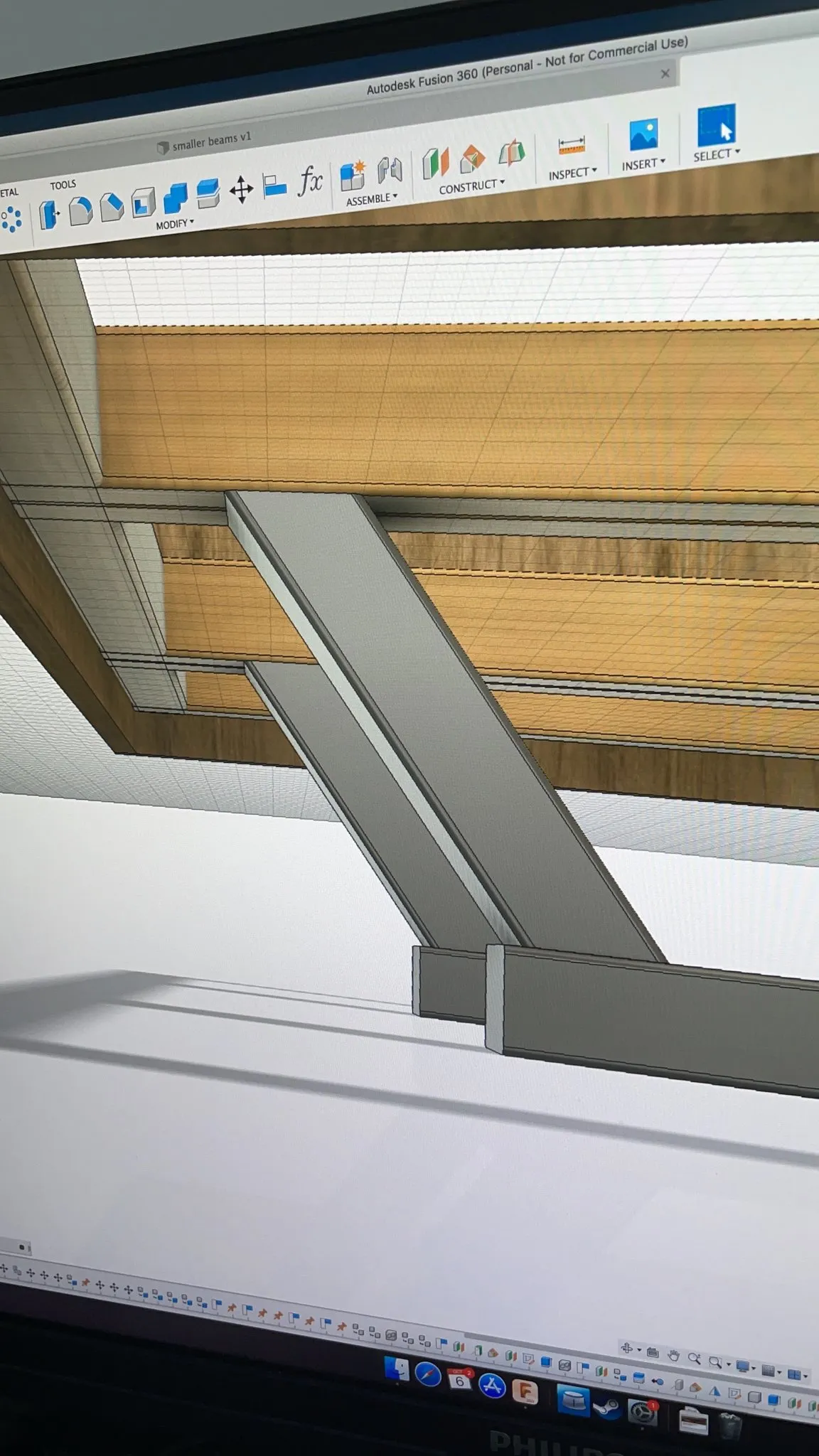

Rough planning was necessary to remove cupping and warping from the logs. The custom router-based flattening jig, built on aluminum rails, allowed us to process the rough stock into perfectly flat, usable lumber. This jig was essential for achieving the precision needed for the final assembly.

Throughout the preparation, we tested the general concept with rough planks to see how the final result would look. This helped us refine our approach and catch potential issues early. Each peg was made to measure for its specific position on the bed, ensuring perfect fit and alignment.

Construction involved building the softwood core and carefully attaching the oak facing. Along with the table saw, a new router was essential for the detailed joinery work. The process required precision at every step to achieve the floating aesthetic while maintaining structural integrity.

The construction phase saw the bed frame take shape piece by piece across four distinct stages. Each component was carefully fitted, with attention to both the visible details and the hidden structural elements. The router work was particularly important for creating clean, precise joints that would be invisible in the final piece. Throughout the build, we used stainless steel SPAX screws for all connections, ensuring long-term durability and resistance to corrosion.

Joinery

Custom router jigs used for precise lap joints and invisible fixings

Finish

Sanded to 320 grit and finished with 3 coats of Danish Oil

Hardware

Stainless steel SPAX screws throughout for durability and corrosion resistance

Stage 1: Building the softwood core structure and establishing the foundation for the oak cladding.

Stage 2: Attaching the oak facing panels and beginning the detailed joinery work.

Stage 3: Refining the oak finish and comparing the finished oak against raw stock to see the transformation.

Stage 4: Final assembly, finishing touches, and integration of the slat system and lighting.

The transformation is dramatic. We moved from a heavy, dark brown old bed to this modern, floating oak design. The new bed makes the room feel larger and more serene, with the integrated lighting creating a warm, ambient glow that enhances the floating effect.

The completed bed frame successfully achieves its design goals: it appears to float, provides robust support, and can be disassembled for future moves. The natural oak finish brings warmth to the space, while the clean lines and thoughtful details create a piece that feels both modern and timeless.

Assembly

Designed for disassembly with carefully planned connection points and hardware

Durability

The bed has successfully moved house with us 4 times, proving the disassembly design works perfectly